Technical Specification:

| Printing speed: | 50-180T/Min |

| Printing color: | 2-6colors |

| Max. printing length: | 350mm |

| Max. web width: | 320mm |

| Max. printing width: | 300mm |

| Max. unwinding diameter: | 600mm |

| Max. rewinding diameter: | 600mm |

| Power supply: | 3 phase 380V |

| Total power: | 33.6kw (without UV power) |

| Main machine size: | 8850mm×1600mm×1850mm(L×W×H) |

| Machine weight: | about 9.5t |

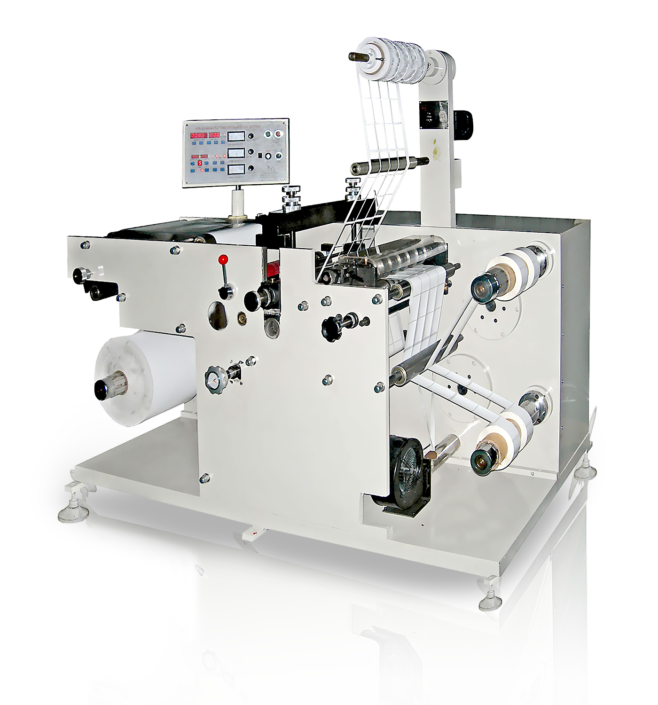

Auto slitting machine with rotary die cutter has total length counter, label counter, predetermined counter, speed adjustment, alarm, pneumatic coreholder & tension control.

Edge guide on unwind is agitated by German made photo-eteclrical eye.

It is a fast running, accurate slitting and rotary die cutter, ease of operation and stable equipment under tight construction.

Web width: 320mm

Die cutter repeat: 10”

Rewinder air shaft diameter 76mm

Slitting speed: 75m/min

Die cutter speed: 60m/min

CE standard

Fumigation wooden case

THE SPECIAL CHARACTERISTICS

- FQ-330R machine adopts exact servo control system which can ensure the stabilization when the printing material in the printing

process. It can Free from the printing roller change. The operation of this machine is fast, convenient and simple. - Pinting unit: adopting high quality and heavy offset printing unit. Assembled with 19 pieces of ink rollers (including 4pcs of Form

Rollers) and 4pieces of Water rollers, has nice ink working system to avoid Streak trouble and Ghost image efficiently, largely

increase the printing quality. The definition and precision made would never be reached by Flexo press. - Shaftless transmission system: every printing unit transmitted by an independent servo motor, 14 sets of servo motors in total

for whole machine (6color) to ensure the exact color registering precision during high speed operation. - Positioning system: The only work is to input the printing length on the main control panel, every printing unit will be motioned to

the presetting position automatically. Largely saves time and materials when adjust the color register. - Color registering system: the vertical and horizontal motions of every printing unit are all controlled by independent motor (ease

the laboring and reduce the waste). By video still system, the machine can regulate vertical & horizontal Registering without

stopping, it improves the printing quality and increases the producing capacity.

- Super Large printing area: 300X350, the maximum perimeter could be reached at 350mm. By high-precision photocells, the

machine ensures multi-register print on both side, make the possibility of label pattern variety. - Every printing unit equips with clutch device to be stopped independently by lifting away when needed. This system extends the

machine using life

8.Multi-options: UV varnishing unit, rotary die-cutting unit are available for option, even Spot UV unit.

Magnetic die-cutting cylinders adopted, on which different patterns only need to replace different flexible die plate, in-line printing

and die cutting, easy operation, low cost, high performance. - Touch LCD screen, faster CPU, 12 inch supper large display area, powerful human-computer dialogue system, multi-guide

inspection display interface, instant alarm signal, makes operation easier, more efficient and save time. - PS plate Intermittent printing adopted, hits the high-level demands whatever high, mid or low capacity printing task, and it is an

ideal choice for print firms to produce the high-grade adhesive labels.